Epoxy Flooring: Proper Treatment of Construction & Control Joints

Epoxy Flooring: Proper Treatment of Construction & Control Joints

Concrete floor slabs have several different kinds of joints, which require different treatment with respect to the installation of resinous flooring. There are three main types of joints: expansion joints, construction joints, and control joints. This article will provide guidance regarding proper treatment of construction and control joints.

Concrete floor slabs have several different kinds of joints, which require different treatment with respect to the installation of resinous flooring. There are three main types of joints: expansion joints, construction joints, and control joints. This article will provide guidance regarding proper treatment of construction and control joints.

Construction and control joints are distinguished from expansion joints in that they are essentially non-moving once the concrete has reached full cure. While sealant used in expansion joints should preserve the joints’ ability to move, systems used to seal construction and control joints are typically rigid.

TIP: You have a choice when it comes to filling construction and control joints. You can use rigid or flexible materials. But, when it comes to expansion joints, choose flexible joint filler. Expansion joints are designed to move throughout the life of the structure. A rigid mortar would eventually crack in an expansion joint.

To fill construction and control joints prior to applying an epoxy-based concrete coating or topping, follow these simple steps:

1. Sawcut joint and vacuum or blow out debris.

2. Prime surfaces of joint with epoxy primer.

3. Fill joint with epoxy mortar. A mixture of epoxy primer and silica flour works well.

4.  Prime concrete floor in a 10- to 12-inch wide strip, bridging the joint.

Prime concrete floor in a 10- to 12-inch wide strip, bridging the joint.

5.  Lay a 4-inch wide strip of chopped strand fiberglass mat onto the primed concrete surface, bridging the joint. One-ounce cloth works well for this purpose.

Lay a 4-inch wide strip of chopped strand fiberglass mat onto the primed concrete surface, bridging the joint. One-ounce cloth works well for this purpose.

6.  Saturate fiberglass cloth with primer and smooth with a small, hard roller to remove air bubbles

Saturate fiberglass cloth with primer and smooth with a small, hard roller to remove air bubbles

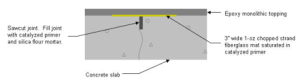

After the joints have been treated in this way, the floor can be primed and coated with a compatible epoxy topping. The construction detail is illustrated below.

This type of treatment is often also suggested to address concrete floor cracks; however, use of a rigid filler system does not always yield long-term success. Concrete cracks because it is moving, and future movement causing a stress riser at the same location can cause the concrete to crack again. Often a new crack will develop immediately adjacent to the original, filled crack. In such cases, a flexible sealant is usually a more practical solution.

Non-moving construction and control joints can mirror through epoxy floor toppings, causing a crack to form in the topping over these joints. Using a combination of epoxy based joint filler and epoxy-saturated, crack-bridging reinforcing fabrics helps prevent reflective cracking. To ensure joints in your next flooring project are treated properly, include this detail in your construction drawings.